Tail blow out, or TBO, happens when the thrust coming from the tail rotor is not enough to counteract the torque coming from the main rotor during fast pitch changes, resulting in an unintentional pirouette.

This is mainly caused, in the case of the mCPX, by the motor not responding quick enough to the inputs of the gyro.

TBO is a major cause for crashes when the pilot steps up from hovering and wants to try to flip or roll the helicopter: sudden pitch variations will cause the tail not to hold anymore, the heli will spin, the pilot loses control, and down she goes...

There are a few solutions to this problem:

- you can add a second motor on the tail to double its effectiveness, like shown here

- you can swap the stock motor for a bigger one, such as the tail coming from the Blade 120SR

- or you can extend the tail boom

I preferred the third option as I found it the easiest...and the cheapest.

What you need to perform this mod is:

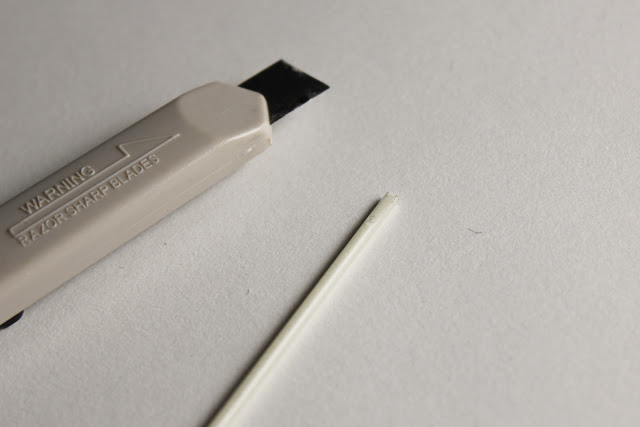

- a length of 2 mm carbon fibre rod (I used fiberglass because I couldn't find any carbon around)

- cutter / X-acto knife

- mCPX tail case and motor

- some CAT 5 wires (optional, I use them because it's a relatively thick copper wire which prevents any voltage drop. It is the wire you commonly find in Ethernet cables.)

- Soldering iron

- Some heat shrink

|

| Check if everything fits properly |

|

| To protect the tiny wires coming out the motor I use the old trick of inserting the motor and motor mount in some 7 mm heat shrink. This way in an impact the assembly is well protected. |

|

| Last thing I added was to cut the wires behind the main shaft, strip them and re-solder them together so that if I need to take the tail apart I won't have to work on the motor or the 3 in 1. |